Pakt Blog - News, Bag Talk, and Packing Tips

The MODE Collection: Day Bags Built for Real Life

Discover the Pakt MODE Collection: Modular day bags designed for seamless travel. Compare the 12L, 14L, and 22L bags to find your perfect daily carry system.

Really remote work: Elizabeth’s year-long global adventure

Elizabeth manages Pakt’s finance and behind-the-scenes operations, keeping everything organized, balanced, and on track. But she’s far from a typical number-cruncher.

"My husband and I both felt this urge to live and travel while we are still young enough to do it. It had always been on his bucket list, and I’ve lived abroad in the past and love adventuring to new countries. Our schedules just happened to align where we had the flexibility to take an extended trip."

Now, about three-quarters of the way through the nearly year-long journey across multiple continents, Elizabeth shares what she’s loved, learned, and how this adventure has helped reset routines, connect with new people, and embrace experiences outside her comfort zone.

The gear

See Product

See Product

Aero Travel Backpack

The Aero Travel Backpack is a breeze at the airport. I can carry it over my rolling luggage and easily access my laptop through security.

Stash Packable Tote

The tote is my go-to bag. Honestly, I carry it everywhere. I’m currently writing this at a coffee shop, and it carried my laptop here. It pretty much always stays packed with a light jacket, umbrella (hello rainy season), water bottle, scarf (for temples), grocery bags, and my camera. And it’s so great I can roll it up and fit it into the Travel Backpack on travel days, so I can travel completely carry-on friendly throughout the whole trip.

The Route

Italy

I learned how to slow down life in Italy. Sit with a glass of champagne and stare at the countryside, journal each morning, walk everywhere, wait for a bus for 40 minutes… It was a great welcome into our travel abroad, coming from our busy lives in LA. Remote work here was super easy: work in the afternoons in between lunch and dinner. Espresso in the afternoons (nothing beats Italian espresso). We stayed in the countryside, and there was just one little cafe about a 5-minute walk, where we got to know the owners. They had some of the best food we ate in Italy.

Spain

We walked the Camino de Santiago, hiking 12–13 miles a day. Every day was a different adventure. Managing remote work after walking for hours every day was a challenge. I took calls from a monastery, albergue, hotel, park, really anything went to manage both work and walking each day!

Portugal

Recovering from the Camino, we went surfing in Porto and reconnected with old friends visiting from our hometown of LA, as well as new ones we met on the Camino. I learned the value of having amazing friends and really just enjoying each day in life: looking out over the river, getting in a groove surfing, and just being present in each day. Remote work became easier with working in the early afternoons out on the balcony.

Turkey

This was hard. We were both sick for our entire two weeks in Turkey. It happens in travel, so I learned a lot about readjusting expectations and just being okay with things not going as planned. We still found time to enjoy little moments, like taking a boat ride on the Bosphorus, and my new favorite Turkish food: Kahvalt - an incredible breakfast spread with cheeses, dips, olives, eggs, and sausages.

Thailand

Balancing work here has definitely been the hardest part of life here, but the culture, food, and community are incredible. I’ve been living off of mango sticky rice and khao soi. We’ve also met a really great digital nomad community here, and everyone is really welcoming and kind.

What’s Next?

"I’m learning to really balance my life more with a daily routine that looks pretty “normal” as my mom says: a balance between physical health, work, and emotional health.

We work out, cook food at home, meet up with friends, and work/study. We do about two to three “touristy” things a week, like seeing elephants, going to temples, or waterfalls."

Elizabeth’s journey continues with Ecuador, an 8-week Spanish course, and one final, still-to-be-determined destination:

"We’d love your input for our last destination! Somewhere we can practice our Spanish, enjoy nature, and travel easily from Ecuador."

Got a recommendation? Drop them in the comments, & look out for more updates to come as we share where in the world Elizabeth is, and how she’s keeping Pakt HQ running from afar.

Stash Packable Bags on the Road: Team Trip Recap

The team tests the Stash Packable Bags on real adventures from airports to backcountry trails. Meet lightweight travel gear that doubles as packable day bags.

Los Angeles, Shot on 35mm film

Follow photographer Brian Chorski as he captures Pakt travel and daily carry bags on his 35mm film camera, appreciating that good things take extra care.

Brooklyn To Bozeman: Pakt’s Hometown Story

Trading the Big Apple for Big Sky country, a new year means a new chapter for the best little bag brand this side of the Rockies.

Factory Tour: Pakt’s Fabric Mill

Come along for an inside look at how our values are woven into your Pakt bag.

Traveling By Duffel with Pakt

From our first duffel to our top-rated travel collection, discover duffel travel tips and the story behind our line of carry-on duffels.

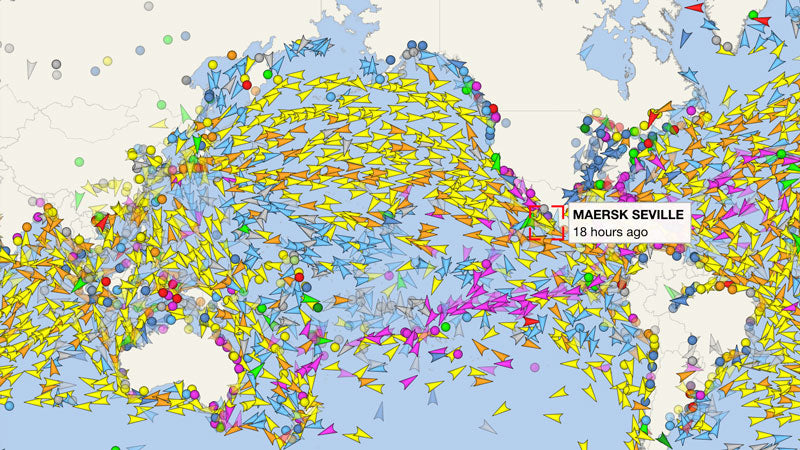

Travel Backpack Production Update: Shipping and Logistics

The journey from a factory in Vietnam to our shipping facility in the US can be unexpectedly long and unpredictable, depending on various outside factors, such as weather conditions, manpower, and even climate change.

Out of stock, again?!

A little background on why you see so many products out of stock right now, from the Pakt founder, Malcolm.